Protecting Construction Workers from Power Lines

Occupational Safety and Health Administration (OSHA)

,

OSHA Office of Construction & Engineering

Summary Statement

Describes risks of electrocution from using cranes, scaffolds, and ladders, discusses the importance of training and provides a card that can be used for training.

Power Lines and Electrocutions

Every day four construction workers die on the job in this country. Think about construction fatalities and probably the first things that come to mind are trenching, accidents, or falls. Yet, the second leading cause of worker deaths in construction (after falls) is electrocution. Many workers are unaware of the potential electrical hazards in their work environment, making them more vulnerable to the danger of electrocution. Sometimes, it is just a matter of not knowing the environment—not being aware of all energized power sources, from overhead and underground power lines to damaged receptacles and connectors."Training and education are key to increasing awareness about electrical hazards in construction," says OSHA's Bruce Swanson, director of the agency's construction directorate. "If we want to reduce the fatality rate, we need to make sure employers and workers are better trained in OSHA requirements and safety work practices."

The primary cause of construction electrocutions is contact with overhead power lines. OSHA data showed that in 1998 and 1999, 277 workers died from contact with overhead power lines. 1

1 U.S. Department of Labor, Bureau of Labor Statistics, Census of Fatal Occupational Injuries, Table 1, "Fatal occupational injuries by event or exposure, 1994-99," (Washington, DC, August 2000). See also www.bls.gov.

A construction worker, while attempting to hook a load to a crane, was electrocuted when the crane's load line contacted an overhead 7,200-volt power line.

Electrocutions occur when workers using cranes, metal ladders, scaffolds, conveyors, front-end loaders, dump trucks, or other equipment or materials come into contact with an overhead power line. All too often, workers die during what appears to be accident-proof activity: unloading supplies from a truck, moving ladders from the side of a structure, adding the final touches to a roofing job—all while near power lines. Poor planning and a moment's inattention may lead to contact with high voltage and death or serious injury.

According to Tom Marple, Director of OSHA's Office of Construction Services in Washington, DC, most construction electrocutions result from "contact with energized sources such as cranes contacting overhead power lines. These injuries show time and again, employers should determine if power sources in the vicinity of workers are live and if the employees could come into contact with them."

The Department of Labor's Bureau of Labor Statistics' data support Marple's claim. Of the 279 workplace electrocutions in 1996, 116 were from contact with overhead power lines. 2 Most workers electrocuted by coming into contact with overhead power lines are working with cranes, working on scaffolds, or using ladders. Construction employers and workers must pay particular attention to distances separating them from high-voltage lines when working on elevated equipment or structures.

Cranes

Overhead power lines and cranes can be a disaster waiting to happen for crane operators and crew members. OSHA data from 1984 through 1994 show that 87 electrocutions occurred to crane operations personnel. 3 The reason is simple. Tall equipment such as a crane with a mobile extension arm can quickly close the safe distance separating it from overhead power lines.

A 20-year-old truck driver died when the boom of a crane he was operating remotely from behind the truck contacted overhead power lines.

OSHA requirements for operating cranes near overhead power lines call for specific clearance distances between work and lines of various electrical loads, safety devices such as boom guards, insulating links or proximity warning devices, and observers, among other things. 4 Good safety sense requires employers and workers to consider all power lines as energized unless the owner of the line or electric utility company indicates otherwise.

Employers, crane operators, supervisors, and others who work around cranes must be fully aware of the hazards of operating cranes near overhead power lines. For example, employers can increase worker awareness of the risk of injury by posting signs at the crane operator's station and outside the crane warning that failing to maintain safe minimum clearances could result in electrocution.

Scaffolds

Workers using scaffolding face hazards similar to those using cranes. When the worker is elevated, the safe distance between the work and energized overhead power lines is shortened. Erecting scaffolds, relocating them, and working on the platform itself all require workers to maintain safe distances from power lines.

Six workers were using a mobile, elevated work platform to install aluminum siding on a warehouse under construction. While relocating the platform, three of the crew died when the top rail contacted a power line.

2 US Department of Labor, Bureau of Labor Statistics, Census of Fatal Occupational Injuries, 1996. See job-related electrocutions by selected characteristics, 1996 and Abstract: "Fatal Electrocutions in the Workplace Profiled." Both are available online at www.bls.gov.

3 Data from OSHA Integrated Management Information System, OSHA's internal database on inspections.

4 Title 29 Code of Federal Regulations (CFR), 1926.550, A-15, Subpart N, "Cranes, Derricks, Hoists, Elevators, and Conveyors."

Clearance between the power lines and scaffolds should be monitored at all times. If a scaffold is to be moved in the vicinity of overhead power lines, a "competent person" 5 should be assigned to observe the clearance and warn others if the minimum distance is not maintained.

But the scaffolding alone isn't the problem. Conductive tools used by workers on scaffolds also contribute to electrocutions. When scaffolds, conductive tools, or other materials contact overhead power lines, workers receive serious and often fatal injuries. Brick masons, carpenters, painters, construction laborers, plasterers, and others who use scaffolding may risk contact with energized overhead power lines. OSHA regulations set forth specific distances that workers on scaffolds must maintain to separate them from power lines. 6 The following minimum clearances must be maintained between scaffolds and exposed, energized power lines:

- 2 feet for insulated

power lines of less than 300 volts, and

- 10 feet for insulated power lines of 300 volts or more and for all uninsulated power lines.

Because the risk of electrocution is high for construction workers on scaffolds, contractors should establish emergency procedures to follow if contact with an overhead power line occurs. These procedures might include keeping all unauthorized personnel away from the area and having workers trained in cardiopulmonary resuscitation available onsite.

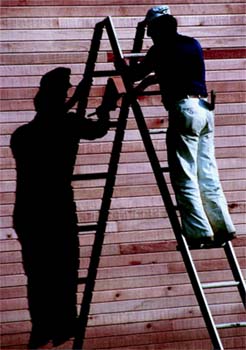

Ladders

Another frequent contributor to electrocutions is ladders. Whether made of metal, fiberglass or wood, ladders extend the reach of workers and the potential for closing the minimum safe distance between workers and energized power lines.

5 A competent person, by way of training and/or experience, is knowledgeable of applicable standards, is capable of identifying workplace hazards relating to the specific operation, is designated by the employer, and has authority to take appropriate actions (see 29 CFR 1926.32). Some OSHA standards add additional specific requirements that must be met by a competent person.

6 29 CFR 1926.451 (f)(6), Subpart L, "Scaffolds."

Two painters were relocating a double-rigged aluminum ladder after painting one side of a warehouse. They lost control of the ladder and it struck a 7,200-volt power line and electrocuted both painters.

OSHA regulations 7 for safely using ladders around overhead power lines require the following:

- Prohibiting the

use of conductive ladders near energized lines.

- Clearly marking

conductive ladders by attaching tags or stickers reading "Caution, do

not use around electrical equipment."

- Using only tools

designed to withstand indicated voltages.

- Keeping ladders at least 10 feet away if the overhead power line is 50,000 volts (50 kilovolts) or less. For higher voltages, keeping ladders at least 35 feet away.

Local training and information efforts can make a significant difference in reducing electrocutions related to overhead power lines. Both OSHA Region VII (Kansas City, MO) and Region IV (Atlanta) have local emphasis programs (LEPS) that have proven effective in averting deaths among construction workers.

OSHA's Kansas City Region, concerned about the frequency of electrocutions caused by overhead power lines, began outreach and training programs for employers and employees in 1999. Area offices contacted individual contractors, insurance companies, labor unions, and associations as well as construction organizations.

"When we determined that 85 percent of construction-related electrocutions in our region involved overhead power lines, we decided to concentrate on that area," notes Marcia Drumm, Deputy Regional Administrator.

7 27 CFR Part 1926.1053 (b)(12), Subpart X, "Stairways and Ladders"; and Part 1926.951 (a)(2)(c), Subpart V, "Tools and Protective Equipment."

Working Around Power Lines: Stay Away! Stay Alive!

|

|

|

|

|

For further information, please refer to the 29 CFR Part 1926. You may also contact your local OSHA area office.

The safety tips on this card are not intended to be all inclusive, they are simply a starting point to help prevent electrocutions from overhead power lines.