Roadway Safety Awareness Program: Trainee Booklet

Laborers' Health and Safety Fund of North America

-

Roadway Safety

The following are links to all of the items in this collection:

Documents

- Roadway Safety: Run Overs & Back Overs

- Roadway Safety: Operator Safety

- Roadway Safety: Struck or Crushed

- Roadway Safety: Flagger Safety

- Roadway Safety: Night Work

- Roadway Safety: Excavation

- Roadway Safety: Electrical hazards

- Roadway Safety: Strains and Sprains

- Roadway Safety: Fall Hazards

- Roadway Safety Awareness Program: Trainee Booklet

- Roadway Safety: Instructor Manual

- Roadway Safety: Working outdoors

- Roadway Safety: Noise Hazards

- Roadway Safety: Health Hazards

- Roadway Safety: Emergencies

Summary Statement

A training booklet that gives an overview of a variety of roadway hazards, such as electrical, falls, slips and trips and ergonomics. It is geared toward a new trainee. Part of a collection. Click on the 'collection' button to access the other items.

2002

| This document is one in a program produced under an OSHA grant by a consortium of the Laborers' Health and Safety Fund N.A, the International Union of Operating Engineers, the American Road and Transportation Builders Assn, and the National Asphalt Pavement Assn. All of the documents from this set that are on eLCOSH can be found by clicking on Job Site, Heavy construction, and scrolling to the Street & highway heading. Or to download a complete version of the computerized program, go to https://www.workzonesafety.org/. |

Building roads and highways can be dangerous. Each year about 7,500 highway construction workers get hurt or sick. More than 80 highway construction workers are killed on the job.

Our work doesn’t have to be dangerous if:

- We are made aware of the hazards,

- We are given ways to avoid the hazards,

- We raise safety concerns with our supervisors.

Electrical Hazards

What Are the Dangers of Electricity?

Contact with electricity can cause explosion, fire, and electrocution. Electricity can cause severe burns and death.

Equipment contacting a live electrical line can cause explosion, fire, or electrocution. Electricity can arc from the line to equipment.

Work around electricity only:

- when you are trained in all aspects of the job, and

- when you have a reason to be there.

Use extreme caution and keep your distance when you must work around above ground utilities. The best practices are:

- Get the utility company to mark, flag, and shield line.

- Assume the line is live until it is tested. Have it de-energized and visibly grounded.

- If the line must remain energized, keep equipment and load at least 10 feet away and use a spotter to warn the operator.

Minimum Safe Distances Power Lines |

|

| Voltage | Distance |

| 50 kV or below | 10 |

| >50-200 kV | 15 |

| >200 - 350 kV | 20 |

| >350 - 500 kV | 25 |

| >500 - 750 kV | 35 |

| >750 - 1,000 kV | 45 |

More in fog or rain |

|

Post warning signs at ground level. Make anyone who must enter the area aware of the overhead lines. Here are two tips for operators:

- Mark a safe route for repeated travel.

- Slow down.

Do not touch equipment or a person in contact with electricity. Get the line de-energized. If you are in a vehicle that contacts electricity, stay in the vehicle and do not contact any metal. If you must exit, jump clear and slowly shuffle away. Keep your feet together to help prevent current from running through your body.

Can We Be Safe Around Buried Utilities?

Before digging, call the electrical, gas, and communications utilities. Review marked out areas. The mark out may not be exact, so dig by hand within 3 feet of it.

When digging, look for:

- foreign debris in excavation,

- changes in mixed-up soil types,

- asphalt patches or depressions indicating previous digging, and

- concrete, plastic, or gravel.

What Causes Falls in Road Work?

Falls happen from one level to another or on the same level. Most falls in road construction are slips or trips on one level. Falls on walking/working surfaces include:

-

• Tripping over materials or debris.

• Falling on hills or embankments.

• Stepping in holes or walking on irregular ground.

• Stumbling while carrying loads that block vision.

• Slips or trips in muddy, wet, or icy conditions.

-

• From equipment.

• From bridges.

• From formwork.

• Into excavations.

Best protection practices include:

-

• Try to avoid muddy, wet, or icy surfaces.

• Use footwear with ankle support and soles that grip.

• Don't carry heavy loads. Use hauling equipment.

• Practice good housekeeping. Remove tools and materials when not in use.

• Fill in or mark hidden holes in the ground.

• Clear walking and working surfaces of tripping hazards.

• Include walking routes in the site safety plan.

A very important way to keep yourself

from falling is to maintain good physical

strength and conditioning.

A very important way to keep yourself

from falling is to maintain good physical

strength and conditioning.How Do We Avoid Falls From Elevations?

Falls from elevations can be avoided by many methods. Some good ways to avoid falls from elevations include:

• The employer should have a 100% fall protection

program in place.

• The employer should have a 100% fall protection

program in place.• Work should be pre-planned to provide for the use of personal fall arrest systems (PFAS) anchor points or guardrail systems.

• Erect guardrails around large excavations.

• Wear seatbelts or restraints for riding in cars, trucks, and personnel carriers.

• Use modular form erection to avoid work at heights on forms.

• Use 3-point contact.

Flagger Safety

What Is the Main Hazard of Flagging?

Motorists kill about 20 flaggers a year. Many more are injured. Flagging can be dangerous due to:

-

• High speed traffic.

• Angry or aggressive drivers.

How Can We Protect Ourselves?

The best way to protect ourselves is to be visible and to wear protective clothing.

Wear high visibility clothing:

-

• Orange, yellow, or green vest.

• Only retro-reflective vests at night.

Wear other protective equipment:

Wear other protective equipment:-

• Hard hat.

• Long-sleeved shirt and pants.

• Appropriate clothes for expected weather.

Follow these tips:

-

• Stand alone on the shoulder

in clear view.

• Never stand in the open traffic lane.

• Plan an escape route for emergencies.

• Stay alert, focused on work.

• Make sure your hand signals don’t conflict with the traffic signals.

• Treat motorists with respect and courtesy. Don’t pick fights or respond to anger. Notify law enforcement when motorists do not obey.

Health Hazards

How Do Health Hazards Harm Us?

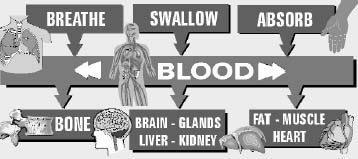

Toxic substances can enter the body by three routes:

-

• breathing,

• swallowing, and

• absorption through the skin.

The effects of toxic substances in the body may be:

-

• short-term (acute) — such as eye irritation or

dizziness, or

• delayed (chronic) — such as cancer or chronic lung disease.

Silica is in many construction dusts such as concrete and rock. Tasks that expose workers to large amounts of silica include sand blasting, rock drilling, and concrete drilling and grinding.

Long-term exposure to silica leads to lung disease (silicosis). Long-term exposure also increases the risk of cancer. You can prevent exposure to silica by:

-

• reducing airborne dust through ventilation and

wetting and

• using NIOSH-approved toxic dust respirators.

Asphalt fumes may cause eye and respiratory tract irritation. Hot asphalt can severely burn the skin.

To prevent exposure to asphalt:

-

• Work upwind whenever possible.

• Maintain a lower temperature to minimize fumes.

• Use ventilation on paving machines.

• Wear gloves and long-sleeved shirts to prevent skin contact.

How Harmful Is Wet Concrete?

Wet concrete can cause dermatitis and skin burns. Dermatitis can be either an irritation from chemicals in the concrete or an allergic reaction. The allergic type is very difficult to cure.

The best practices for preventing dermatitis and burns include:

-

• Wear long-sleeved or gauntlet gloves.

• Keep concrete out of your boots.

• Change your gloves and your boots if they become contaminated inside.

• Wash your hands in clean water with pH-neutral soap.

• Try using a neutralizing or buffering product.

• Protect all cuts with bandages.

• Wear eye protection.

Lead damages the nervous system and the reproductive system. Lead may be found in paints during bridge renovations. Lead dust and fume can be inhaled or ingested during sandblasting, welding, and cutting. Lead dust can be carried home on clothes and can poison your family.

Prevent lead poisoning by:

-

• Removing

paint before

cutting or

welding.

• Using longhandled torches.

• Using local exhaust ventilation.

• Wearing the proper respirator.

• Washing face and hands before eating, smoking, or drinking.

• Showering and changing clothes before leaving work.

• Getting your blood level tested periodically.

Other health hazards include common substances like solvents and carbon monoxide or special products such as sealants and paints. To avoid health hazards:

-

• Review the product Material Safety Data Sheets.

• Limit exposure as much as possible.

• Stay upwind of hazardous exposures.

• Make sure hazard controls like fans are working.

• Wear protective gear like respirators and skin coverings.

• Promptly report health complaints to your supervisor.

What Are the Special Challenges of Night Work?

On the worksite, the challenges include:

-

• Poor visibility for motorists.

• Poor visibility for workers.

• Communication between shifts.

• Impaired or drowsy drivers.

-

• Sleep deprivation and disruption.

• Risk of injury from drowsiness.

• Impaired family or social relationships.

Use special precautions at the work site for night work. Above all, you must increase visibility and know your surroundings.

To increase visibility:

-

• Wear retro-reflective clothing.

• Wear flashing lights on your body or clothing.

• Place retro-reflective tape on equipment.

• Use good work area lighting.

Know your surroundings:

-

• Know the vehicle and equipment paths.

• Know the assigned work areas.

• Know the safe paths to and from work.

• On foot, watch out for equipment.

• On equipment, watch out for workers.

Inspect the traffic control set up by test driving it to highlight problems and then inspecting it frequently.

How Can Our Health Habits Help?

Night work is not normal. You must compensate and

your health habits can make a huge difference. On the

work site, eat protein-rich foods and avoid sugars and

fats. Drink plenty of water and avoid caffeine.

Night work is not normal. You must compensate and

your health habits can make a huge difference. On the

work site, eat protein-rich foods and avoid sugars and

fats. Drink plenty of water and avoid caffeine.At home, make sleep a priority. Follow a pre-sleep routine and have a light snack before bedtime. Keep daylight out, even if you have to install black out drapes. Eat family meals together and plan daytime social activities. That way, you’ll be ready for sleep when you come home from work.

Noise Hazards

Is Too Much Noise a Serious Problem?

If you are exposed to too much noise, you can lose your hearing — and you can lose your life.

On the job, too much noise can distract you. You may not hear warnings. Noise also damages the nerves in the inner ears. These nerves cannot be repaired.

After 15 to 20 years in the trade:

-

• You may suffer permanent hearing loss.

• You may hear constant ringing in your ears (tinnitus).

What Noise Sources Are Most Common?

What Noise Sources Are Most Common?There are many noise sources in road construction. Some of the most common include:

-

• heavy equipment,

• pile driving,

• pavement breakers,

• traffic.

Yes. There are efforts to make it quieter. Noise levels can be reduced by:

-

• Buy or rent quieter

equipment.

• Keep equipment well maintained.

• Move noisy equipment away from workers.

• Put sound barriers around equipment.

The best way to protect your hearing now is to wear

personal protective equipment (PPE).

The best way to protect your hearing now is to wear

personal protective equipment (PPE).If you must shout to talk with someone 3 feet away, you need ear protection.

Use the PPE provided by your employer. Notify your employer if the PPE is not proper. Make sure your PPE fits and is comfortable. Follow the manufacturer’s instructions for use.

Get a hearing test about once a year so you’ll know your hearing protection is working.

Operator Safety

How Can Operators Stay Safe?

Safe equipment operation includes these practices:

Safe equipment operation includes these practices:-

• Before starting vehicle, do a walk-around inspection.

• Test the back-up alarm and other safety devices.

• Locate and test controls.

• Know the equipment blind spots and the swing radius.

• Use equipment seatbelts.

-

• Climb with 3 points of contact to avoid falls.

• Look for other moving equipment or vehicles.

• Wipe up grease and fluid on equipment walking/working surfaces.

Stay alert and aware of the hazards. Report all repair

needs to your supervisor. Always lock out and tag out

equipment that cannot be operated. For general safety:

Stay alert and aware of the hazards. Report all repair

needs to your supervisor. Always lock out and tag out

equipment that cannot be operated. For general safety:-

• Use personal protective equipment (PPE) supplied

and required by your employer.

• Never use cell phones, AM/FM radios, CD players, or other distractions while operating equipment.

• Safely secure equipment before using employerprovided hand-held cell phones or walkie-talkies.

• Secure unattended equipment.

• Lock-out/tag-out before repair or maintenance. Set the parking brake and chock the wheels.

The operator has special responsibilities. Know the job:

-

• Know the work zone and your position in it.

• Know the internal traffic control plan.

• Use designated equipment routes and areas.

• Identify rollover hazards.

• If you must move cones or barricades, return them to their original positions as soon as possible.

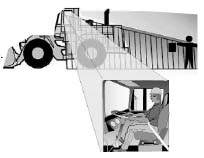

How Can We Protect Other Workers?

Keep other workers in mind:

-

• Know the locations of other

workers around you.

• Set up a means of communication with them.

• Never allow them to ride on equipment.

• Provide barriers between workers and equipment, when possible.

• Avoid excess speed and dangers caused by hills, obstacles, and curves.

What Is Our Risk from Sun Exposure?

Skin cancer is the most serious

risk. You are at greater

risk if you have lighter skin

with freckles or moles. Work

at higher elevations and work

around relfective material like concrete or water also

Skin cancer is the most serious

risk. You are at greater

risk if you have lighter skin

with freckles or moles. Work

at higher elevations and work

around relfective material like concrete or water also

-

• A long-sleeved shirt and pants in neutral colors.

• A broad-brimmed hat with a neck flap.

• Safety glasses with tinted polarizing lenses.

• SPF 15-25 sun block applied 30 minutes before work and reapplied every 2 to 3 hours.

• Frequent checks of skin for early signs of cancer and seeing a dermatologist for check-ups.

Plants and animals can cause rashes, illness, and even death. Outdoor work can expose you to animal bites, such as from dogs or snakes, and to plants like poison ivy and poison oak. To prevent problems:

-

• Steer clear of any animals.

• Learn to recognize, avoid poisonous plants.

• Wear long-sleeved shirts and pants.

• Check for tick bites each day.

• Get prompt treatment.

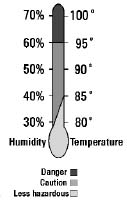

Hot weather can lead to heat stress, heat exhaustion, or

heat stroke. Heat illness can be caused by a combination of:

Hot weather can lead to heat stress, heat exhaustion, or

heat stroke. Heat illness can be caused by a combination of:-

• Heat exposure.

• High humidity.

• Non-breathing synthetic clothing.

• Not drinking enough fluids to replace sweat.

• Hard work, body heat, not being "acclimatized."

What Is Heat Exhaustion?

Heat exhaustion is a dangerous illness. Symptoms include:

-

• Extreme weakness or fatigue.

• Dizziness, confusion.

• Nausea.

• Clammy moist skin

• Pale or flushed complexion.

• Slightly elevated body temperature.

What Is Heat Stroke?

Heat stroke can cause hallucinations and death. Symptoms are red or spotted hot dry skin, no sweat, chills, high body temperature, mental confusion, and slurred speech. Call 911. Remove the victim to a cool shaded area. Soak clothes with water. Fan the body and apply ice to bring down temperature.

To protect yourself:

-

• Wear light-colored clothing.

• Gradually build up to heavy work.

• Schedule heavy work during coolest parts of day.

• Take more breaks in extreme heat and humidity.

• Drink lots of water, at least 2 to 3 quarts a day.

Cold stress can lead to hypothermia and frostbite. Cold stress is caused by a combination of cold or cool temperatures (50o F or less), wet weather and/or conditions, high winds (40+ MPH), and inadequate clothing.

-

• Wear warm layers of correct clothing.

• Wear a head cover, warm gloves, and wool socks.

• Breaks in warm areas and hot liquids.

• Keep in good physical shape.

• Keep dry.

Can We Be Safe Near Equipment and Traffic?

Being struck is the biggest danger in road work. Workers on foot must remain alert at all times. Check surroundings often. Listen for warnings. Keep a safe distance from traffic. Stay behind barriers where possible. Look out for each other. Warn coworkers.

What Other Precautions Do We Need?

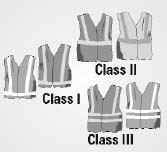

What Other Precautions Do We Need?Employers must provide proper personal protective equipment (PPE). Workers must wear it:

-

• Proper class of safety

vest at all times in the

work zone.

• High-visibility clothing and headgear.

What About Construction Equipment?

What About Construction Equipment?Treat equipment and vehicles with caution:

-

• Stay out of "blind spots.”

• Communicate with operators by radio and/or eye contact.

• Don't approach until you communicate with the operator and he/she acknowledges you.

• Stay outside a "safety circle" around equipment. If you can’t see the operator, he/she can’t see you.

• Stay clear of vehicles. Know the traffic control plan.

• Use spotters when you must work with your back to equipment or traffic.

Yes. Workers must follow company safety policy:

-

• Follow all safety rules and practices.

• Avoid horseplay and reckless behavior.

• Ask for instructions if you don't understand.

• Join in safety discussions. Ask questions. Share your knowledge and experience.

• Employers are responsible for determining whether employees understand the information.

How Are Road Workers Struck or Crushed?

Tools and materials are two major hazards. To avoid being struck by tools:

-

• Use point of operation guarding on portable hand tools.

• Use a chain saw safety program.

• Use Personal Protective Equipment (PPE).

-

• Keep out of lifting areas, from beneath loads.

• Use safe methods for rigging, hoisting, and setting steel plates, jersey barriers, manhole frames and covers.

• Use PPE — hard hats, footwear, eye protection.

Trees and equipment maintenance are also hazards.

To avoid being struck by trees, restrict worker access

during felling, trimming, loading. Use protective structures

on equipment. Use safe hoisting, rigging for logs

and limbs.

Trees and equipment maintenance are also hazards.

To avoid being struck by trees, restrict worker access

during felling, trimming, loading. Use protective structures

on equipment. Use safe hoisting, rigging for logs

and limbs.To avoid being struck by equipment parts, do lockout/tagout and hazardous energy control during maintenance, repair, cleaning, and inspection.

Sprains & Strains

Sprains & StrainsWhat Injuries Are Most Common?

About 43% of lost work day injuries in roadway construction are sprains and strains. Common injuries include:

-

• Hand and wrist problems.

• Back injuries.

• Sprains, strains, and overexertion.

Think of the most difficult parts of your job. These

injuries may be caused by some of these tasks, like:

Think of the most difficult parts of your job. These

injuries may be caused by some of these tasks, like:-

• Working in awkward

postures, such as raking

asphalt.

• Handling heavy materials, like in concrete formwork.

• Repetitive work, like rebar tying.

• Using vibrating tools like a pavement breaker.

• Whole body vibration for operators.

Think of ways to do the job differently. We can make our work easier:

-

•

Minimize manual materials handling with dollies,

hoists, and other equipment.

Minimize manual materials handling with dollies,

hoists, and other equipment.• Better job planning (deliver materials where they're used).

• Store materials for easy access.

• Use tools that are comfortable and easy to handle.

• Wear PPE, like kneepads and shoulder pads.

• Wear PPE, like kneepads and shoulder pads.• Take breaks when possible, rotate difficult and easier tasks.

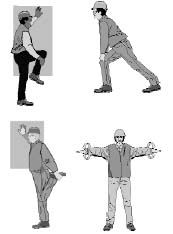

Do at least some of these measures:

-

• Plan and maintain a clear, level

walking path.

• Don't lift too much by yourself. Get help.

• Use proper lifting technique. Lift with your legs, not your back when possible.

• Do stretching exercises before work.

• Keep fit.

Why Are Trenches Dangerous?

A trench is an excavation deeper than it is wide. Trenches can kill:

-

• Workers can be buried alive.

• Cave-ins can result from stresses in walls, nearby moving vehicles and equipment, or spoil piles.

• Water can collect in the bottom.

• Flammable and toxic gases can build up.

• Gas from nearby sewer or gas lines can seep into the trench.

-

• Call electrical, gas, and communications utilities.

• Use extreme caution with equipment.

How Do We Prevent Cave-Ins?

Protective systems are the methods or structures that protect us from cave-ins. A protective system must suit the soil type, the depth of the excavation, and other site conditions. It must resist without failure all loads intended or reasonably expected to be put on it.

The primary types of protective systems are:

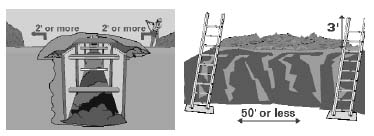

| • Sloping — soil angled to increase stability |  |

| • Benching — steps in the trench wall. |  |

| • Shoring — a support system made of posts, wales, struts, and sheeting or hydraulic shoring. |  |

| • Trench Shielding — a protective frame or box to protect rescue workers after a cave-in |  |

Trenches 5 feet or deeper require support unless they are in stable rock.

What Else Does Trenching Require?

The employer must designate a 'competent person' in every trench job. The ‘competent person’ must inspect:

-

• At least daily and at the beginning of each shift.

• After precipitation, a thaw, and other events that could increase hazard.

• For disturbed ground, water, toxics, and other hazards.

• If walls sag or crack or if the bottom bulges.

• To keep spoil at least 2 feet from trench edge.

• If there are nearby vibration sources such as railroads or piledriving.

• That no worker is more than 25 feet from an exit ladder.

Competent person means "one who is capable of identifying existing and predictable hazards in the surroundings or working conditions ... and who has authorization to take prompt corrective measures to eliminate them."