Summary Statement

One-page summaries of over 100 NIOSH-supported construction safety and health research projects in 2002.

2003

WORK ORGANIZATION ISSUES IN CONSTRUCTION: THE RELATIONSHIP BETWEEN OVERTIME AND INJURY

RESEARCHER: Linda GoldenharAFFILIATION: Division of Applied Research and Technology National Institute for Occupational Safety and Health (513) 558-6936

PURPOSE: Examine the relationship between working overtime and injury among construction workers.

RESEARCH SUMMARY: Research has shown that working extended periods of overtime may be detrimental to the safety and health of workers. This feasibility study will look at the relationship between working extended periods of overtime and injuries among construction workers through secondary data analysis and interviews with construction workers. This project alone will not provide definitive answers as to the associations between construction-work-related organizational issues and health and safety. However, it should provide some understanding of important relationships that can be further explored in larger studies.

The specific research questions to be investigated are (1) What is the relationship between working extended overtime hours and injury among construction workers? (2) Do injury rates increase after working a particular number of hours per week? (3) Is the relationship between hours worked and injury greatest among workers in high-risk trades or in jobs requiring heavy manual labor? (4) Are there specific trades that require more overtime? (5) What are the major factors that affect workers' schedules? (6) What are workers' perceptions of the hazards of working overtime?

This study includes a quantitative and a qualitative component. The quantitative component will be an analysis of data from the National Longitudinal Survey of Youth 1979-1996. This is a study of a representative sample of people who have been surveyed on annual basis from the time they were 14 to 22 years old in 1979 through 1996. The survey provides detailed information on work histories, work scheduling, and work-related injuries and illnesses. It is unique in that it includes data on the self-employed and both union and nonunion workers.

Qualitative data obtained from interviews with construction workers will be used to supplement the quantitative findings to provide some insights into issues not identified through quantitative statistical methods. The qualitative analyses should provide a more comprehensive picture of the relationship between the work organization variables of interest and safety and health, for example, how workers' experiences and perceptions of working overtime affect health and safety on the job or whether self-employment is related to the ability to self-regulate hours worked and therefore to quit when fatigued.

KEYWORDS: Work organization, injuries

RECENT CITATIONS:

Goldenhar, L.M., S. Hecker, S. Moir, and J. Rosecrance. Developing a model of overtime in construction: Not too much, not too little, but just right. Journal of Safety Research (submitted).

Goldenhar, L.M., S. Hecker, S. Moir and J. Rosecrance. 2002. Developing a model of overtime in construction: A qualitative investigation. Presenta-tion at 8th annual Qualitative Health Research Conference, Banff, AB, April 4, 2002.

Goldenhar, L.M., S. Hecker, S. Moir and J. Rosecrance. 2002. A model of overtime in construction: Not too much, not too little, but just right. In Power Through Partnerships: 12th Annual Construction Safety and Health Conference, Proceedings (May 21-23, 2002, Rosemont, IL).

WORK SCHEDULING, OVERTIME, AND WORK-RELATED INJURIES IN CONSTRUCTION

RESEARCHER: Sue Dong

AFFILIATION: CPWR – Center for Construction Research and Training (301) 578-8500

PURPOSE: Examine work scheduling in construction and identify any association between work scheduling and overtime and work-related injuries.

RESEARCH SUMMARY: Research has shown that work organization factors, including work schedules and working extended periods of overtime, may be detrimental to the safety and health of workers. As described in the National Occupational Research Agenda, these factors may contribute to occupational injury, work-related musculoskeletal disorders, cardiovascular disease, and other occupational health concerns. Very few studies, however, have looked at this particular work organization variable within the construction environment and identified whether it has any negative impact on the safety and health of construction workers.

This study tries to answer the following research questions: (1) What are typical work schedules in construction and what differences in work scheduling exist between construction and other industries, (2) how is work scheduling influenced by factors such as economic conditions, technology, demographics, and employment performance, and (3) how does work scheduling and overtime affect the safety and health of construction workers.

The National Longitudinal Survey of Youth (1979 cohort) was used for this study. Initial findings are that (1) work scheduling in construction is different from scheduling in other industries, (2) hours worked per week and weeks worked per year increased steadily for all workers (construction and other industries) in this cohort during the study period, (3) injured workers were more likely to have worked overtime before being injured, and (4) overtime was significantly associated with work-related injuries in construction, especially for construction laborers, after controlling for sex, age, occupation, employment size, and other potential confounders.

KEYWORDS: Work hours, overtime, work organization

RECENT CITATIONS:

Dong, X. 2002. Scheduling/overtime and work-related injuries in construction. In Power Through Partnerships: 12th Annual Construction Safety and Health Conference, Proceedings (May 21-23, 2002, Rosemont, IL).

Dong, S., with R. Chowdhury, M. McCann, C. Trahan, and J. Gettleman. J. Seegal, editor. 2002. The Construction Chart Book: The U.S. Construction Industry and Its Workers, 3rd ed. Silver Spring, MD: CPWR – Center for Construction Research and Training.

ACUTE EYE INJURY EPIDEMIOLOGY

RESEARCHER: Larry Jackson

AFFILIATION: Division of Safety Research National Institute for Occupational Safety and Health (304) 285-5980

PURPOSE: Characterize occupational eye injuries through epidemiologic investigations of surveillance and workers' compensation data, conduct detailed telephone interviews with injured workers and industrial groups, and assess protective eyewear equipment use.

RESEARCH SUMMARY: Eye injuries account for about 5% of work-related injuries. Based on data from the National Electronic Injury Surveillance System (NEISS), more than 260,000 occupational eye injuries were treated in emergency departments in FY96 and FY97. The highest rate of eye injuries, 16%, was to construction workers. A majority of the injuries were due to foreign bodies in the eye and could have been prevented by appropriate use of personal protective equipment. However, in most cases, safety eyewear was not used or inappropriate eyewear was worn.

The primary focus of this work is on understanding the causes of and preventing acute eye injuries in the construction industry. Results will include a series of epidemiologic publications that will help define the nature of eye injuries in the workplace and the specific risk factors for injury. In addition, data will be collected to support the development of standards on eye and face protection and health communications for effective intervention techniques to prevent eye injuries. Through this work, we hope to assist the American National Standards Institute in developing new standards to best protect workers from occupational eye injuries.

The NEISS database was used to gain an all-industry perspective of eye injuries in the workplace and to focus attention on eye injuries among construction workers. A follow-back study and telephone interviews investigating the use of personal protective equipment and failure were conducted. The evaluation of injury reports and investigations from a large database of project compensation among construction workers is continuing. In addition, we are collaborating with West Virginia University to study eye injuries identified in the West Virginia Workers' Compensation database.

KEYWORDS: Eye injury, protective equipment

RECENT CITATIONS:

Disaster rescue and recovery worker-eye safety, available at (in English) www.cdc.gov/niosh/eyesafe.html; (in Spanish) www.cdc.gov/spanish/niosh/docs/eyesafeSP.html.

Sweeney, M.H., D. Fosbroke, L. Gol-denhar, L.L. Jackson, K. Linch, B.D. Lushniak, C. Merry, S. Schneider, and M. Stephenson. 2000. Health consequences of working in construction. In Construction Safety and Health Management, R.J. Coble, J. Hinze, and T.C. Haupt, eds. Upper Saddle River, NJ: Prentice-Hall, pp. 211-234.

A STUDY OF ERGONOMIC INTERVENTIONS IN THE DRYWALL INDUSTRY

RESEARCHER: Christopher Pan

AFFILIATION: Division of Safety Research National Institute for Occupational Safety and Health (304) 285-5978

PURPOSE: Access the ability of current interventions to reduce the magnitude of biomechanical stresses induced on a body during handling, hanging, and finishing drywall sheets.

RESEARCH SUMMARY: On the basis of workers' compensation data from 21 states, drywall installers were ranked as one of the top four occupations at increased risk for occupational injury among 30 common construction specialties.

- A recent NIOSH study indicated that nearly half the injured drywall installers suffered sprains, strains, and tears, mostly to the back. About one-third of the trunk injuries occurred while lifting solid building materials, mainly drywall.

- In a survey of drywall installers, concern was expressed by workers that wearing stilts put them at greater risk for overexertion and increased the likelihood they would be involved in a fall than when they were using a ladder or scaffolding. The causal relationship between stilt use and fall and overexertion injuries will be evaluated using a dynamic biomechanical modeling approach to evaluate different loads and impacts (e.g., joint forces) from various hazards while using stilts and two-man lifts. Secondly, gait analyses of hanging/finishing tasks using stilts will be conducted.

- It is hypothesized that teamwork techniques may reduce disc compression forces in workers. However, two-man lifts may create coordination problems between two workers, which might lead to additional fall and trip injuries. Therefore, biomechanical stress levels when workers perform two-man lifts to handle drywall sheets will be assessed.

- Another component of the project is to measure the interface between the skin on the hand and the drywall sheet by measuring friction coefficient and grip force. A measurement device will be developed as a prototype tool for measuring grip and feed forces. If the grip force and duration of handling are identified as having the potential to cause injuries, a protective glove will be recommended to accompany handling methods.

KEYWORDS: Traumatic injuries, safety, ergonomics

RECENT CITATIONS:

Pan, C.S., S. Chiou, H. Hsiao, and J. Wassell. 1999. Assessment of perceived traumatic injury hazards during drywall hanging. International Journal of Industrial Ergonomics, v. 25, no. 1, pp. 29-37.

Pan, C.S., and S. Chiou. 1999. Analysis of biomechanical stresses during drywall lifting. International Journal of Industrial Ergonomics, v. 23, pp. 505-511.

Chiou, S., C.S. Pan, and P. Keane. 2000. Traumatic injuries among drywall installers, 1992 to 1995. Journal of Occupational and Environmental Medicine, v. 42, no. 11.

ANALYSIS OF CONSTRUCTION FALL ACCIDENTS

RESEARCHER: Jimmie Hinze

AFFILIATION: University of Florida (352) 392-4697

CONSORTIUM: Construction Safety Alliance

PURPOSE: Analyze the various aspects of construction fall accidents to identify their primary or root causes.

RESEARCH SUMMARY: OSHA analyzed 2,741 fall accidents in the construction industry for the years between 1990 and 2001. Results showed that most occurred at elevations of less than 30 feet and primarily involved the construction of commercial buildings and residential projects. Many were the result of worker misjudgment of hazards in the work environment. Worker experience did not appear to affect the number of fall injuries.

Despite OSHA's emphasis on protecting workers from falls, falls still constitute a growing proportion of all construction accidents.

Falls need not be a part of any construction worker's experience and can be prevented through effective project design and careful evaluation of working conditions. Training and proactive preventive measures can reduce fall accidents in construction.

KEYWORDS: Falls, fall prevention, hazard identification

RECENT CITATIONS:

Huang, X., J. Hinze, and J.D. McGlothlin. (In press.) Analysis of construction worker fall accidents. Journal of Construction Engineering and Management.

Hinze, J., X. Huang, and J. McGlothlin. 2002. Review of fall accidents in construction. Presentation at 10th International Symposium on the Organization and Management of Construction, Construction Innovation, and Global Competitiveness, Cincinnati, OH, Sept. 9-13, 2002.

HAZARD RECOGNITION TRAINING TO PREVENT FALLS IN CONSTRUCTION

RESEARCHERS:

-

Ted Scharf (513) 533-8170

Division of Applied Research and Technology

Carol Merry Stephenson (513) 533-8581

Education and Information Division

Kathleen Kowalski (412) 386-4531

Lynn Rethi (412) 386-6686

Bill Wiehagen (412) 386-6468

Bobbie Calhoun (412) 386-4652

John Haggarty (412) 386-6464

Pittsburgh Research Laboratory

PURPOSE: Develop and evaluate two training interventions (a simulation exercise and a hazard recognition program) to be carried out in collaboration with safety personnel in a stadium or similar construction setting.

RESEARCH SUMMARY: Falls from heights were the single biggest risk in the construction industry in the 1980's, accounting for one-quarter of all fatalities. In data compiled in 1998, 32.7% of all deaths were the result of falls. Among roofers, structural metal workers, carpenters, and painters, one-half of all deaths in 1994 were from falls. This trend continued in the 2000 data where 32% of all deaths in construction were due to falls. Therefore, developing and evaluating training interventions that can reduce risks for falls is essential if we are to help achieve national safety and health objectives.

The interventions proposed will actively encourage the ability to recognize hazards and respond in an appropriate manner. An approach developed in the mining industry will be customized for the work environment in heavy construction by promoting (1) the ability of construction workers to recognize hazards in the workplace and (2) active judgment and decision-making by construction workers in hazardous conditions.

Under an existing collaborative project between NIOSH and Pennsylvania State University, two training interventions that will help reduce the risk of falls in construction are nearing completion. The first is a fully documented hazard recognition training exercise related to risks for falls from heights during heavy construction. The second is a companion simulation exercise that focuses on decision-making and how people integrate hazard recognition and communication with response alternatives in a heavy construction work setting. Both interventions require one or two more field validation tests.

KEYWORDS: Hazard recognition, intervention evaluation, falls, heavy construction

RECENT CITATIONS:

Ramani, R.V., M.C. Radomsky, J.P. Flick, G. Russell, T. Scharf, K. Kowalski, B. Calhoun, L. Rethi, W. Wiehagen, C.M. Stephenson, and J. Haggerty. 2002. Hands-on fall prevention hazard recognition training using degraded 3-D images. In Power Through Partnerships: 12th Annual Construction Safety and Health Conference, Proceedings (May 21-23, 2002, Rosemont, IL).

DYNAMIC SCAFFOLD MODELING FOR FALL PROTECTION

RESEARCHER: Mathew Hause

AFFILIATION: Division of Safety Research National Institute for Occupational Safety and Health (304) 285-5982

PURPOSE: Develop a methodology for determining force magnitude and direction on a fall protection anchorage point as a function of variables such as anchorage point rigidity and type of fall protection equipment.

RESEARCH SUMMARY: Falls continue be one of the leading causes of fatalities in the construction industry. OSHA regulations require that a competent person determine the feasibility and safety of fall protection for employees erecting or dismantling supported scaffolds. One method of providing this protection in the absence of an anchor to a permanent structure would be to tie off to scaffolding. This project is intended to help determine whether scaffolding has sufficient stability to serve as fall protection anchorage in the absence of other anchorage during scaffold erection and dismantling and is based on inquiries from external partners.

Current methods do not measure the direction of the force on an anchor and therefore cannot be used to determine scaffold stability for a variety of scaffold configurations. Laboratory investigations and computer modeling will be used to develop methods of determining the forces (directions and magnitudes) on fall protection anchor points as a function of variables such as anchor point rigidity and fall protection equipment type. Methods will be developed for measuring the force in a lanyard and the direction of that force as functions of time. A fully instrumented, articulated, 95th-percentile manikin will be used for drop tests.

The results of this project will be used in a follow-on study to determine the family of forces on anchor points as a function of point rigidity. This family of curves will help determine under what conditions, if any, scaffolding may be used as a fall protection anchor and therefore may influence OSHA's nonmandatory recommendations for fall protection during scaffold erection.

KEYWORDS: Scaffolding, falls, protective equipment

RECENT CITATIONS:

Hause, M. 2001. Dynamic scaffold modeling for fall protection. Poster session, NIOSH Morgantown High Bay Laboratory Tours.

National Institute for Occupational Safety and Health. 2000. Worker deaths by falls: A summary of surveillance findings and investigative case reports. DHHS (NIOSH) Pub. 2000-116.

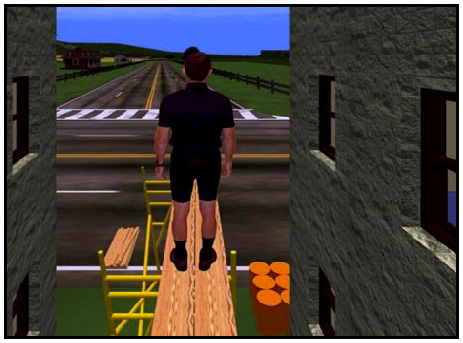

INFLUENCE OF VISUAL CUES WORK AT HEIGHTS

RESEARCHER: Douglas Ammons

AFFILIATION: Division of Safety Research National Institute for Occupational Safety and Health (304) 285-5910

PURPOSE: Study the effects of the visual cues of height and restricted space on worker performance as a predictor of falls.

RESEARCH SUMMARY: Falls from elevated work surfaces are the major cause of construction-related injuries and fatalities. NIOSH's National Traumatic Occupational Fatalities (NTOF) surveillance system confirms that the construction industry suffers a disproportionate number of fatalities resulting from falls from elevations. From 1980 through 1989, 6,012 fatal falls were recorded in the NTOF surveillance system. Of these fatal falls, 2,551 (42%) were falls from elevations and occurred in the construction industry.

It is suspected that a worker's perception of height and a restricted work space contribute significantly to falls. The effects of the visual cues of height and restricted space on workers' performance will be investigated through the use of a virtual workplace created by a mini-supercomputer and virtual reality software. The subjects will be immersed in this virtual workplace where they will stand on an elevated scaffolding board. The effects of changes in plank and platform widths will be examined at various virtual heights and walking speeds while workers perform various work tasks. It is hypothesized that standing instability, walking unsteadiness, and cardiovascular reactivity will increase as the perceived work space width is decreased, height is increased, or lighting level is diminished.

The information from this study will lead to a better understanding of the minimum and optimal width requirements of platforms for scaffold workers to safely perform their tasks at various heights and under different environmental conditions. Results will also provide information regarding the benefits and possible limitations to incorporating virtual reality systems into occupational safety research.

KEYWORDS: Falls, scaffolding, virtual reality

FALL PREVENTION RESEARCH IN CONSTRUCTION

RESEARCHER: Michael McCann

AFFILIATION: CPWR – Center for Construction Research and Training (301) 578-8500

PURPOSE: Develop and implement a fall prevention research program in construction.

RESEARCH SUMMARY: In 1999, falls were the leading cause of death in construction, causing 31% of work-related deaths. An analysis of Census of Fatal Occupational Injuries data from the Bureau of Labor Statistics for the years 1992-1999 showed that the major causes of deaths from falls were falls from roofs (33%), scaffolds (18%), ladders (14%), and girders or other structural steel (10%). One finding was that at least 16% of what were classified as falls were actually collapses or tipovers of the surfaces the workers were standing on. For example, 54% of the falls from suspended scaffolds, 19% of the falls from supported scaffolds, and 19% of the falls during the erection of steel structures were due to collapses.

One-hundred-thirteen supported scaffolds across the eastern United States were inspected using a detailed checklist that included information about the "scaffold-competent" person on the site and the structural stability and fall hazards of the scaffolds. There was a strong correlation between structural flaws and missing planks, guardrails, and/or inadequate access. Correlations were found between proper scaffold safety practice and (1) the presence of a competent person who claimed to have had scaffold safety training, (2) nonframe scaffold types, and (3) erection of the scaffold by a separate contractor trained in the process.

A fall protection system for workers installing decking inside a controlled decking zone is being evaluated. This system consists of running a cable through predrilled holes in columns 7 ft above deck level, with a third cable attached to the two other cables. Shock-absorbing lanyards can be attached to any of the three cables, providing fall protection for workers. The effective-ness of erecting stable columns during the set-up of steel structures is being evaluated also.

A third intervention involves collaborating with NIOSH researchers in developing and implementing checklists for extension ladder set-up and use. These checklists are ready for field evaluation as toolbox talks.

Other collaborators on this project include the Ironworkers Union, Capaco Steel Industries, the University of Kentucky, Kentucky Employers Mutual Insurance, and Werner Co.

KEYWORDS: Scaffolds, structural steel, falls, collapses, tipovers, ladders, competent person

RECENT CITATIONS:

McCann, M., and D. Paine. 2002. When is a fall not a fall? In Power Through Partnerships: 12th Annual Construction Safety and Health Conference, Proceedings (May 21-23, 2002, Rosemont, IL).

Halperin, K., and M. McCann. 2002. An evaluation of supported scaffold safety. In Power Through Partnerships: 12th Annual Construction Safety and Health Conference, Proceedings (May 21-23, 2002, Rosemont, IL).

Lineberry, G.T., T. Scharf, R. Jameson, M. McCann , R. Sulecki, and W. J. Wiehagen. 2002. An educational intervention for extension ladder set-up and use. In Power Through Partnerships: 12th Annual Construction Safety and Health Conference, Proceedings (May 21-23, 2002, Rosemont, IL).

PREVENTION OF FALLS FROM ELEVATIONS IN THE CONSTRUCTION INDUSTRY

RESEARCHERS:

James D. McGlothlin

Purdue University

Jimmie Hinze

University of Florida (352) 392-4697

CONSORTIUM: Construction Safety Alliance

PURPOSE: Identify key elements leading to worker injuries and fatalities resulting from falls from elevations in the construction industry and devise strategies to prevent them.

RESEARCH SUMMARY: More than a million people suffer from a slip, trip, or falling injury each year. Slips, trips, and falls account for 15% to 20% of all workers' compensation cases, with older construction workers having a higher percentage of falls compared to younger workers. Of those who suffer fatal injuries, more were involved in falls than in any other single cause. This has been a consistent statistic for many years. In a study of construction workers between 1985 to 1989, it was determined that falls accounted for 33% of worker deaths. More recently, analyses of data from OSHA data show a slight increase in fall fatality incident rates in this industry.

This study investigated 15 large construction and four residential roofing companies. The construction companies were selected by Purdue researchers based on their strong safety programs and low incidence rates of "falls from elevations." Many of these companies had won safety awards from the Association of General Contractors (AGC).

The investigation has three goals.

- To investigate the relationship between safety program effectiveness (using a standardized questionnaire) between large construction companies and small residential roofing companies.

- To develop an information database on work risk factors associated with falls from elevations among residential roofers.

- To conduct a laboratory study to evaluate differences between balance and age among active residential roofers.

The laboratory study is just beginning, and results are not available at this time.

KEYWORDS: Residential roofers, falls from elevations

RECENT CITATIONS:

Huang, J., J. Hinze, and J.D. McGlothlin. 2002. Analysis of construction worker accidents. Presentation at 10th International Symposium on the Organization and Management of Construction, Construction Innovation, and Global Competitiveness, Cincinnati, OH, Sept. 9-13, 2002.

Potts, S., J.D. McGlothlin, and J. Hinze. 2002. Prevention of fatal falls in the construction industry. Poster session at American Industrial Hygiene Conference, San Diego, CA.

AERIAL LIFT SAFETY RESEARCH IN CONSTRUCTION

RESEARCHER: Michael McCann

AFFILIATION: CPWR – Center for Construction Research and Training (301) 578-8500

PURPOSE: Develop and implement a program on the safe use of aerial lifts in construction.

RESEARCH SUMMARY: Aerial lifts (including both boom-supported lifts and scissor lifts) cause the deaths of about 26 construction workers each year according to Census of Fatal Occupational Injuries data from the Bureau of Labor Statistics for 1992-1999. The leading causes of death were electrocution (33%), falls (31%), and collapses/tipovers (22%). Issues identified were lack of training in the use of particular models of aerial lifts, lack of personal fall protection devices, maintenance problems, lack of standardization of controls, and traveling while the lift was elevated and occupied.

Aerial lift interventions for 2002-2003 include a study of actual work and maintenance practices involving aerial lifts. This work will involve collaboration with NIOSH and ATL International in a 4-year research project on aerial lifts.

KEYWORDS: Falls, collapses, tipovers, boom, buckets, scissor lifts

RECENT CITATIONS:

McCann, M. 2002. Aerial lift safety in construction. In Power Through Partnerships: 12th Annual Construction Safety and Health Conference, Proceedings (May 21-23, 2002, Rosemont, IL).

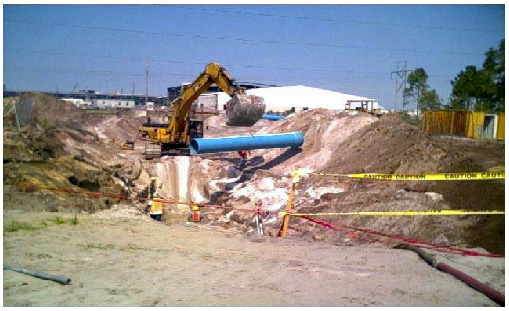

ASSESSING THE RISKS OF INJURY IN TRENCHING AND EXCAVATION IN THE UNITED STATES

RESEARCHER: Patrick J. Coleman

AFFILIATION: Spokane Research Laboratory National Institute for Occupational Safety and Health (509) 354-8065

PURPOSE: Assess the risks of injury to workers digging, working in, and working near trenches and excavations, with a primary focus on risks from the collapse of trench walls, and make recommendations for further research or changes in the regulations dealing with management of hazards caused by trenching practices.

RESEARCH SUMMARY: This pilot study examines the issue of why construction and other workers continue to die in trench collapses despite the existence of extensive OSHA regulations governing the sloping, shoring, and shielding of trenches. The project includes identifying databases of case reports of injuries resulting from trench collapse, gathering and analyzing these data, and applying analytic techniques such as fault-tree analysis. These techniques allow a researcher to identify key variables in the causal chains leading to accidents and to explore ways of controlling hazardous factors and conditions. These studies will be followed by statistical analyses of OSHA and Bureau of Labor Statistics data on trenching fatalities, which will provide a first look at the most common reasons for such accidents. The work will be supplemented by field investigations of selected cases to obtain additional facts. We will interview a number of companies doing trenching work and workers who have been involved in trench collapse accidents.

A parallel effort will be to evaluate common economic activity indicators, such as numbers of new housing starts. Such statistics may provide an index to the number of workers working in and around trenches and to measures of activity, such as the number of "trench feet" opened per month.

KEYWORDS: Trench safety, risk assessment, excavation

RECENT CITATIONS:

Coleman, P.J. 2002. Assessing the exposures and risks of trenching and trench collapses in the U.S. In Power Through Partnerships: 12th Annual Construction Safety and Health Conference, Proceedings (May 21- 23, 2002, Rosemont, IL).

DEVELOPING SAFER TRENCHING OPERATIONS

RESEARCHERS:

Dulcy M. Abraham

Purdue University (765) 494-2239

Jimmie Hinze

University of Florida (352) 392-4697

CONSORTIUM: Construction Safety Alliance

PURPOSE: Identify the major causes of accidents and develop strategies to prevent fatalities and reduce injuries in trenching operations.

RESEARCH SUMMARY: Each year, there are over 100 hundred estimated fatalities in the United States associated with excavations and trenching operations. According to a NIOSH analysis of workers' compensation claims in the Supplementary Data System of the Bureau of Labor Statistics (BLS), there are approximately 1,000 work-related injuries each year due to excavation cave-ins. To improve the effectiveness of accident prevention programs in trenching operations, the primary causes of trenching accidents and fatalities have to be identified.

The approach adopted in this study has utilized three major avenues.

- Analysis of historical fatality data from trenching operations.

- Interviews with safety directors from construction companies.

- Job site visits.

To date, the major causes of fatalities have been correlated using two accident causation models - namely, the Type of Accident Model and the Human Behavior Model. Plans are underway to develop an analytical tool to assist safety directors in the selection of appropriate safety strategies for trenching operations under differing site conditions.

The research findings from Dr. Jimmie Hinze's study on trench shield accidents will be integrated into this project. Dr. Hinze is also conducting a nationwide survey in which information on the use of trench shields is sought directly from contractors who use trench shields.

KEYWORDS: Fatalities, trenches, safety, accidents

RECENT CITATIONS:

Arboleda, C., D.M. Abraham, R. Wirahadikusumah, and J. Irizarry. 2002. Trench-related fatalities in construction: An analysis of fatality assessment and control evaluation (FACE) records. In First International Conference on Construction in the 21st Century (CITC2002): Challenges and Opportunities in Management and Technology (Miami, FL, April 25-26, 2002.), pp. 277-282.

Lew, J., D. Abraham, R. Wirahadi-kusumah, J. Irizarry, and C. Arboleda. 2002. In Excavation and trenching safety: Existing standards and challenges. Third International Conference on Implementation of Safety and Health on Construction Sites (Hong Kong/Beijing, China, May 8-17, 2002). (Available on CD-ROM)

Irizarry, J., D.M. Abraham, R. Wira-hadikusumah, and C. Arboleda. 2002. Analysis of safety issues in trenching operations. Presentation at 10th International Symposium on the Organization and Management of Construction, Construction Innova-tion, and Global Competitiveness, Cincinnati, OH, Sept. 9-13, 2002.

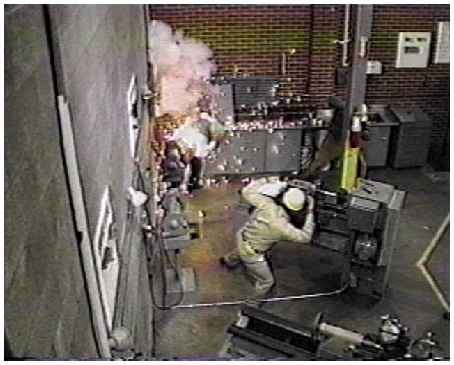

ELECTRICAL ARC INJURY PARAMETERS AND PREVENTION

RESEARCHER: Mary Capelli-Schellpfeffer

AFFILIATION: CapSchell, Inc. (773) 960-5802

PURPOSE: Develop computerized three-dimensional models of electrical arcing events and apply these models to a severity rating of blast conditions.

RESEARCH SUMMARY: Electrocution is the second most common cause of construction-related fatalities in the United States. In 1992, the Bureau of Labor Statistics reported over 540,000 electrical workers in the United States. Among those workers, 1994 data show that 11,153 cases of reported days away from work were due to electrical burns, injuries from electrocution/electrical shock, and fires and explosions. The Census of Fatal Injuries noted that out of a total of 6,588 work-related fatalities, 548 employees died because of exposure to an electrical current, fire, or explosion. In the U.S. chemical industry, 56% of the fatalities over a 5-year period were attributable to burns, fires, or explosions, many of which were ascribed to an electrical ignition source.

The clinical spectrum of electrical injury ranges from the absence of any external physical sign to severe multiple trauma. Reported neuropsychiatric damage can vary from vague complaints seemingly unrelated to the event to damage consistent with traumatic brain injury. In part, blast effects may explain why patients without external signs of electrical contact may present nervous system or hearing impairments; however, no causal link has ever been established to guide treatment.

This project takes advantage of previously collected data from staged scenarios of electrical arcing events. Three-dimensional models will be used to simulate electrical and workplace conditions to study the interaction of acoustic forces and workers during electrical arcing events. A blast severity rating based on simulation results will be compared to 500 actual electrical injury incidents. The comparison between numerical simulations of acoustic forces and experimental data is expected to result in improved safety standards for work practices around energized equipment.

This project is essential to addressing the lack of data and analysis concerning the interaction of acoustic forces and workers during electrical arcing events. By obtaining more complete and accurate data, treatment and prevention strategies can be improved with applied technical knowledge in medicine, engineering, and safety management.

KEYWORDS: Fatalities, traumatic injuries, electrical, blast

RECENT CITATIONS:

Capelli-Schellpfeffer, M., C. Kalina, M. Toney, J. Mitchell, and R.C. Lee. 2001. Partnerships for electrical safety. IEEE Industry Applications Society Magazine, v. 7, no. 3, pp.17- 22.

Capelli-Schellpfeffer, M. 2002. Electrical arc flashes and unexpected explosions. In Power Through Partnerships: 12th Annual Construction Safety and Health Conference, Proceedings (May 21- 23, 2002, Rosemont, IL).

Capelli-Schellpfeffer, M., G. Miller, and M. Humilier. 1999. Thermo-acoustic energy effects in electrical arcs. Annals of the New York Academy of Science, v. 888, pp. 19- 32.

ELECTRICAL SAFETY RESEARCH IN CONSTRUCTION

RESEARCHER: Michael McCann

AFFILIATION: CPWR – Center for Construction Research and Training (301) 578-8500

PURPOSE: Develop and implement an electrical safety research program in construction.

RESEARCH SUMMARY: Electrical deaths in construction were analyzed for the years 1992-1998 using Census of Fatal Occupational Injuries data from the Bureau of Labor Statistics. Of the 1,019 deaths (146 per year), 1,002 were due to electrocutions and 17 were due to electrical arc flashes. Electrical workers (electricians, electrical power installers, and repairers; their apprentices and helpers doing electrical work; and their supervisors) had one-third of the electrical deaths, followed by laborers. The cause of over half of the electrically caused deaths of electrical workers was contact with "live" energized equipment and wiring resulting from failure to de-energize and lockout or tagout electrical circuits and equipment and failure to use appropriate personal protective equipment and tools. For nonelectrical workers, the main cause of electrocution was contact with overhead power lines, which caused over half the electrocutions. Working too close to energized electrical equipment and wiring, failure to lockout or tagout machinery and appliances before working on them, faulty electrical cords, and lack of ground fault circuit interrupters were causes of many of the other electrocutions.

An intervention project for electricians involves computerization of the International Brotherhood of Electrical Workers (IBEW) injury and illness reporting forms. To date, 350 reports have been computerized and analyzed. Problems with standardization and missing data were identified and are being corrected for use in an on-line injury and illness reporting system by IBEW locals. The resulting data will be analyzed for the purpose of targeting high-risk activities. This system could also serve as a surveillance model that could be adapted by other building trades affiliates.

A survey of work practices by electricians has been developed and will be distributed nationally by the IBEW. Other research interventions being developed for electrical workers include training in lockout/tagout procedures and evaluation of a permit system for working with live electrical circuits.

For nonelectrical workers, an intervention has been developed to evaluate the effectiveness of weekly inspections of electrical equipment at construction sites using a detailed checklist. This will include number and types of electrical hazards found, as well as a determination of how long it takes to abate the problems.

George Washington University is also collaborating on this project.

KEYWORDS: Electrical, arc flash, electrocution, lockout/tagout, "live" work permit, checklist, interventions

RECENT CITATIONS:

McCann, M., and R. Chowdhury. 2002. Causes of electrocutions among construction workers. Poster presentation at NIOSH NOIRS 2000, Pittsburgh, PA.

McCann, M., K.L. Hunting, J. Murawski, R. Chowdhury, and L. Welch. 2002. Why construction workers are getting electrocuted. In Power Through Partnerships: 12th Annual Construction Safety and Health Conference, Proceedings (May 21-23, 2002, Rosemont, IL).

Hunting, K., J. Gittleman, M. McCann, M. Mederos, and J. Tomaseski. 2001. A model approach for union-based injury and illness tracking. Presentation at Workshop on Best Practices in Workplace Surveillance: Identification and Tracking of Workplace Injury, Illness, Exposures, and Hazards, Cincinnati, OH, Nov. 7-9, 2001.

Back to Contents